Wine is the perfect companion to cheese or a good meal. Most people know the old ‘stomp your feet in a barrel’ way of making wine, but these days most wineries use oil-free compressed air to automate the process to save time and costs.

Winemaking involves five major stages – harvesting, crushing and pressing, fermentation, clarification, and finally ageing and bottling.

HARVESTING

The first step in the winemaking process is collecting the grapes. The time of harvest varies from year to year and is determined primarily by the ripeness of the grape. Harvesting can be done either by hand or mechanically.

- A mechanical harvester works by beating the vine with rubber sticks to get the grapes to drop onto a conveyor belt which moves them into a holding bin.

- A human worker harvests the grapes by picking them off the vines in bunches and placing them in bins.

After the grapes are sorted, they are ready to be de-stemmed and crushed.

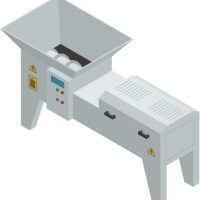

Crushing and pressing involve the use of machines that require a large amount of compressed air. These are comprised of an air compressor and air accelerator that fills the bladder press.

The bladder press crushes the grapes and firmly pushes them against a large sieve that gently squeezes the remaining juice out.

CRUSHING AND PRESSING

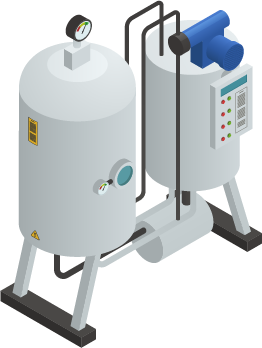

FERMENTATION

Fermentation turns the grape juice into an alcoholic drink! This reaction can happen naturally or be aided with commercial yeasts which speed up the process.

The yeasts convert the available sugars from the juice into alcohol and carbon dioxide. The level of sweetness of the wine depends on the time fermentation is stopped. For example, to create dry wine, fermentation will continue until all sugars are converted into alcohol. To create a sweet wine, winemakers will stop the process before all of the sugar is converted.

No one wants to drink a cloudy wine. This is where clarification comes in. Clarification is the process of removing dead yeast cells, tannins, and proteins. It can be done by fining or filtration.

- Fining occurs when ‘fining agents’ are added to the wine to remove suspended particles and other compounds.

- Filtration occurs by using a filter to capture the larger particles in the wine. The clarified wine is then racked into an oak barrel or a stainless steel tank and prepared for bottling or future aging.

CLARIFICATION

AGEING AND BOTTLING

Wine is either bottled right away or left in the oak barrel or steel tank for further ageing. The oak barrel produces a soft, rounded and smooth wine with hints of oak, whereas the stainless steel tank produces a more zesty wine.

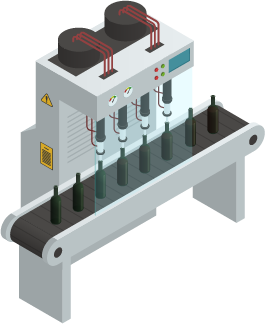

After ageing, wines are bottled and sealed with either a cork or a screw cap, depending on the wine maker’s preference.

Bottling is one of the most common uses for air compressors as it uses a lot of air.

Looking to buy and air compressor, but don’t know which type of air compressor is the best for your application? Contact our NPS Compressed Air Specialists on 08 9333 4940