Understanding compressed air pressure and flow

What is compressed air pressure?

Pressure is the measure of force that’s applied to an area and determines the compressor’s ability to perform a specified amount of work at any given point in time. Each pneumatically powered device has a stated pressure range in which it works reliably, and these limits must not be exceeded.

Pressure, typically measured in pounds per square inch (psi), determines the system’s ability to perform a certain amount of work at any given point in time. To check the psi of your existing system, look at the air gauge on the air compressor – this is where the system pressure will be displayed.

What is compressed air flow?

Flow, as a measure of volume, indicates the rate at which a system delivers output. The amount of airflow required depends on how long a task takes to complete. If a compressor doesn’t have sufficient flow for the job, it will need to stop and rebuild pressure in the tank. Flow is typically measured in cubic feet per minute (CFM) at a specific pressure.

How do pressure and flow work together in your compressor?

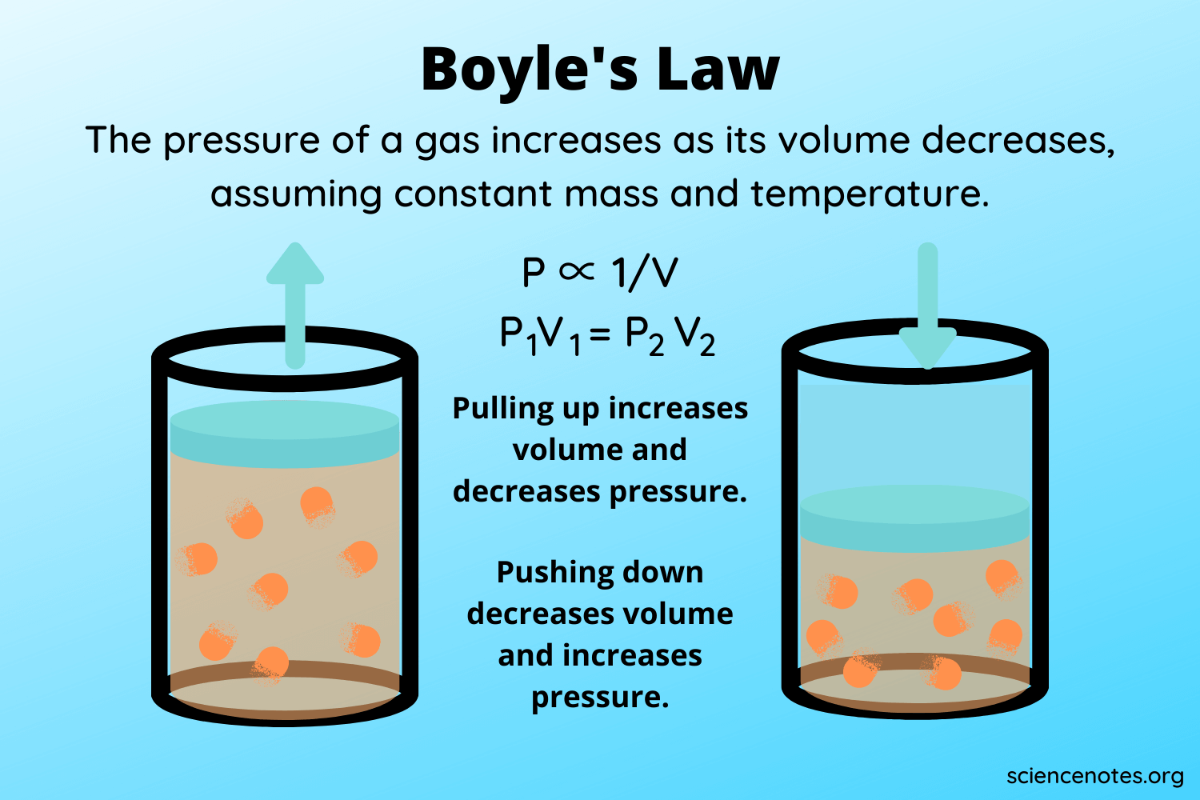

Boyle’s Law states that the pressure of an ideal gas is inversely proportional to the volume under conditions of constant mass and temperature. When the gas volume increases, pressure decreases. When the volume decreases, pressure increases. Boyle’s Law takes its name from chemist and physicist Robert Boyle, who published the law in 1862.

Compressor overpressurisation

Let’s recap

For a given compressor, such as a 50-hp (37.3 kW) unit, the flow will decrease as pressure increases, and vice versa. Therefore, it’s important to purchase a compressor that optimises flow and pressure.

And keep in mind that every 2 psi (0.14 bar) increase in pressure results in 1 percent more energy needed to maintain the same airflow (cfm).

If you have any questions about the pressure or flow rate required for a given application, call our compressed air specialists for expert advice.

Concerned about your compressed air pressure or air flow?

Nessco Pressure Systems knows how important it is to have reliable air supply to power your operations.

If you’re concerned about air flow or efficiency, or if you’re experiencing service issues, call our service team on 1300 290 638 or email info@nesscopressure.com.au and we’ll arrange for a service technician to investigate the issues and get you up and running.