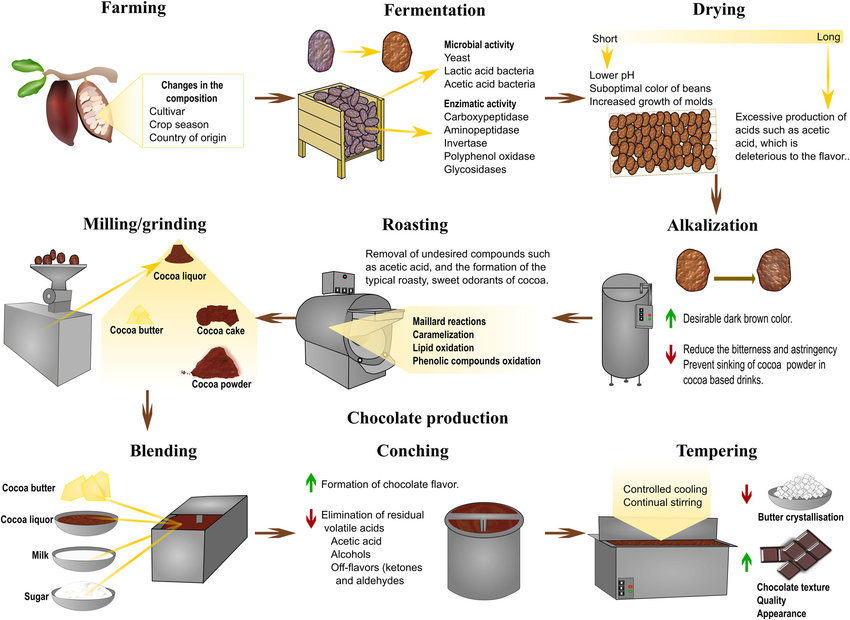

Stages of Chocolate Manufacturing

1. Fermentation of cocoa beans – Fermentation is the first critical process to develop the beans’ natural flavors. The principal effect of fermentation is to eliminate or drastically reduce astringency and to develop the full cacao flavor.

2. Drying/Milling – After fermentation, the cocoa seeds must be dried before they can be scooped into sacks and shipped to chocolate manufacturers.

3. Roasting and Winnowing – After roasting, the beans are “winnowed” to remove the shells from around the bean, leaving only the roasted cocoa nib, which is the key ingredient for making chocolate.

4. Grinding – Grinding is the process by which cocoa nibs are ground into ” cocoa liquor”, which is also known as unsweetened chocolate or cocoa mass.

5. Blending – After the mixing process, the blend is further refined to bring the particle size of the added milk and sugar down to the desired fineness. The Cocoa powder or ‘mass’ is blended back with the butter and liquor in varying quantities to make different types of chocolate or couverture.

6. Conching – The penultimate process is called conching. Conching further refines the chocolate mass with continued grinding. It is at this stage in manufacturing where the maker adds more ingredients such as sugar, milk powder (only if making milk chocolate) and other ingredients and flavorings

7. Tempering and Molding – The final process in making chocolate is called tempering. Uncontrolled crystallization of cocoa butter typically results in crystals of varying size, some or all large enough to be clearly seen with the naked eye

See the entire process of chocolate making, all the way from plant to shop, with full explanations of every step of the process.